Bronze Backed Bimetal Bush

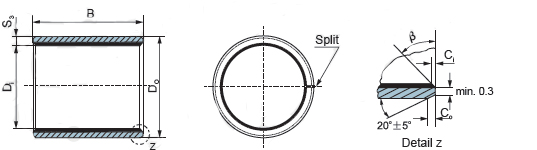

ID and OD Chamfers

| S3 | Co | Ci | β |

| 0.75 | 0.5 ÷ 0.3 | 0.25 ÷ 0.2 | 30o ÷ 5o |

| 1.00 | 0.6 ÷ 0.3 | 0.30 ÷ 0.2 | 30o ÷ 5o |

| 1.50 | 0.7 ÷ 0.3 | 0.50 ÷ 0.3 | 30o ÷ 5o |

| S3 | Co | Ci | β |

| 2.00 | 1.2 ÷ 0.4 | 0.50 ÷ 0.3 | 30o ÷ 5o |

| 2.50 | 1.8 ÷ 0.6 | 0.6 ÷ 0.3 | 45o ÷ 5o |

Unit:mm

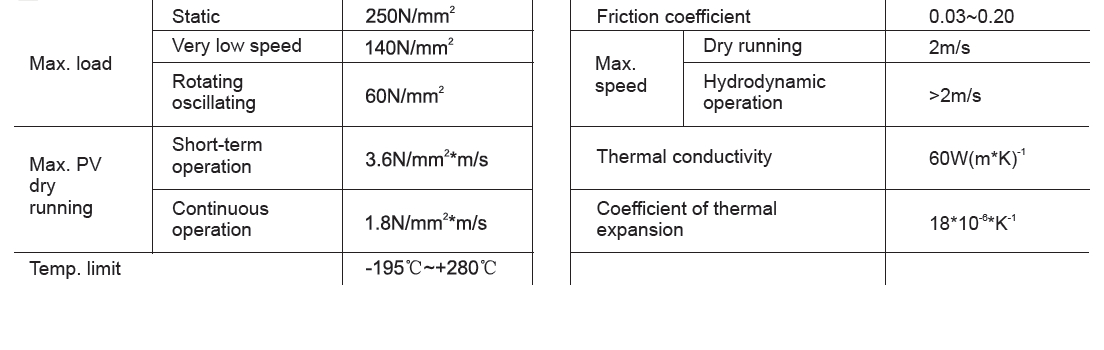

Operating Performance

Dry

Good

Oil lubricated

Very Good

Grease lubricated

Good

Water lubricated

Good

Process fluid lubricated

Good

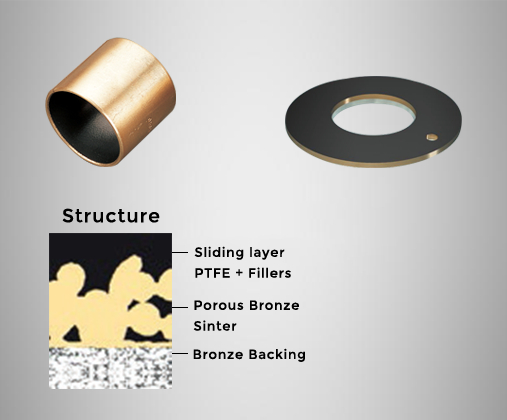

Structure of the material:

| Layer | Average analyses of the material | Thickness of layer |

|---|---|---|

| Sliding layer (Minimum) |

PTFE Coating | 10µm |

| Intermediate layer (Average Peak) |

CuSn11 Sintered | 200 ÷ 350µm |

| Supporting shell | Bronze (CuSn8P) | 0,50 ÷ 2,70 mm (Depending on Dim. of the Bearing) |

Good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

Very good performance in lubricated applications

Good performance in greased applications

Suitable for linear, oscillating and rotating movements

Lead-free material compliant to EVL, WEEE, and RoHS specifications

Suitable for linear, oscillating and rotating movements

Bearing forms available in standard dimensions

Cylindrical bushes

Flanged bushes

Sliding plates

Bearing forms made to order:

Standard forms in special dimensions, thrust washers, flanged thrust washers, half-bearings, special shapes obtained by stamping or deep drawing, bearings with locating notches, lubricant holes and machined/stamped grooves

Civil engineering, marine and o shore equipment, other applications in water or in outdoor environments, etc.